Blog

The Distinctive Advantages of Vertical Mills Over Horizontal Mills

2024.02.22

Introduction

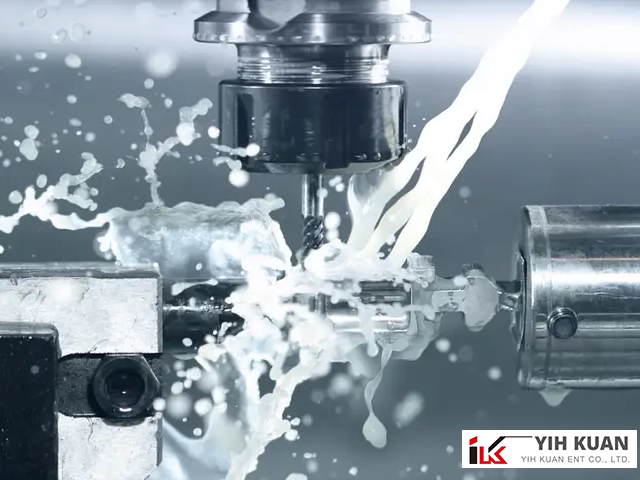

In the diverse world of milling and machining, the choice between vertical and horizontal mills plays a pivotal role in shaping manufacturing strategies across a plethora of tasks. Yih Kuan Ent Co., Ltd., with a keen focus on "vertical mill," delves into the exceptional benefits and applications of vertical milling machines. This exploration aims not only to highlight the unique attributes of vertical mills but also to draw a clear contrast with their horizontal counterparts, shedding light on the distinct advantages and efficiencies each type contributes to the machining landscape.

Vertical Mills: Precision Engineering at Its Finest

Vertical milling machines, characterized by their vertically oriented spindles, are the epitome of precision and versatility. Their adeptness at handling detailed work renders them indispensable for producing complex parts.

Advantages of Vertical Mills:

- Enhanced Precision: The vertical orientation facilitates more precise cuts and superior control over the machining process.

- Versatility in Applications: Capable of managing a wide array of machining tasks, from intricate parts to unique designs, vertical mills are remarkably versatile.

- Space Efficiency: Their compact design makes vertical mills ideally suited for smaller workshops, optimizing workspace without compromising on performance.

Horizontal Mills: The Powerhouses of Material Removal

In contrast, horizontal mills feature horizontally oriented spindles, distinguishing themselves as powerhouses in heavy-duty cutting and bulk material removal.

Advantages of Horizontal Mills:

- Robust Cutting Ability: With their capacity to manage heavy and large workpieces, horizontal mills epitomize strength and power.

- Efficient Material Removal: Designed for speed and efficiency, these mills excel at removing large volumes of material.

- Cost-Effectiveness for High-Volume Production: The rapid material removal capabilities make horizontal mills the preferred choice for large-scale manufacturing endeavors.

Key Differences: Vertical vs. Horizontal Mills

- Orientation and Flexibility: The vertical orientation of the mill's spindle provides enhanced flexibility and precision for intricate parts machining, while the horizontal mill's configuration is optimized for heavy-duty tasks and bulk material removal.

- Application Suitability: Vertical mills are the go-to for detailed and precise machining tasks such as milling, drilling, and tapping, whereas horizontal mills are better suited for extensive cutting operations like slotting and grooving.

- Space and Cost Efficiency: Vertical mills offer space and cost advantages, making them ideal for smaller setups or workshops with limited space. Horizontal mills, although larger, bring efficiency and productivity gains in high-volume production settings.

Yih Kuan Ent Co., Ltd.: Revolutionizing Precision with Vertical Mill Solutions

At the forefront of milling head manufacturing in Taiwan, Yih Kuan Ent Co., Ltd. is committed to pushing the boundaries of vertical milling. Our extensive product range, including the pinnacle of milling technology like CNC Vertical and Horizontal Machining Center Heads, is designed to elevate precision, performance, and versatility. Our dedication to innovation is evident in our specialized CNC Milling Heads and CNC Mill / Traditional Bed Boring and Milling Mills, each crafted to meet the stringent demands of vertical milling applications. Our solutions are synonymous with unmatched precision and efficiency, providing a solid foundation for precision machining across various industries. YIH KUAN's commitment to addressing the diverse needs of our clients ensures that each vertical milling solution we offer is a testament to our relentless pursuit of precision engineering and innovation.

Conclusion

The fundamental distinction between vertical and horizontal milling processes is critical for selecting the most suitable milling equipment for diverse manufacturing requirements. YIH KUAN ENT CO., LTD.'s vertical milling solutions, celebrated for their precision and adaptability, are engineered to excel in creating detailed and accurate components. Concurrently, our horizontal milling capabilities, including CNC Gantry (Plano) Milling Heads and CNC Milling Heads, deliver unmatched efficiency in rapid material removal and large-scale project management. As Taiwan's leading manufacturer in the Milling Heads for Machine Tools sector, YIH KUAN ENT CO., LTD. stands at the forefront of milling technology, offering an extensive selection of products from CNC Vertical and Horizontal Machining Center Heads to specialized Turret Milling Heads and Replacement Milling Machine Heads suitable for both Bridgeport-Type and Bed-Type machines. Our commitment is to provide custom-engineered solutions tailored to the unique needs of our clients, ensuring superior machining performance, accuracy, and productivity across all applications. With YIH KUAN's advanced milling heads, our clients are equipped to reach the zenith of machining excellence, supported by our unwavering commitment to innovation and quality.

For those looking to enhance their manufacturing capabilities with our state-of-the-art milling solutions, YIH KUAN ENT CO., LTD. invites you to reach out. Connect with us to discuss how our precision engineering can benefit your projects and explore tailored solutions designed to meet your specific needs. Contact us today to embark on a journey of machining excellence and innovation.