Blog

What Is a Vertical Milling Machine?

2023.09.20

Whether you are in the market for a used vertical milling machine or are shopping for your first one, it is important to understand what you will be looking for. In its simplest form, a vertical milling machine is essentially a drill press with additional features. This type of machine is typically used in industrial or commercial applications.

This article will provide a brief overview of what a vertical milling machine is, its parts, controls, and things to consider when shopping for one.

What Is a Vertical Milling Machine?

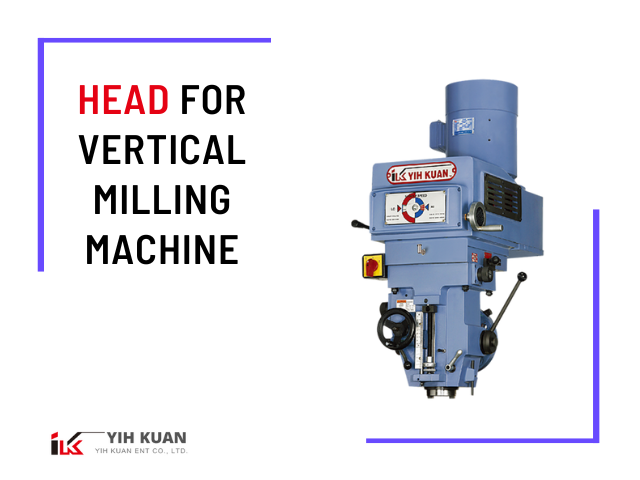

A vertical milling machine is a type of machine used to shape and cut materials such as metal, plastic, wood, or other solid items. It has a vertical spindle axis that is perpendicular to the workpiece. The head of the machine is able to move in an up-and-down direction, as well as all directions across the workpiece.

Vertical milling machines are used in many operations, including making flat surfaces, grooves, slots, and other shapes. This type of machine is also great for engraving and drilling, as it can easily get into tight spots and make high-precision cuts. The machine is ideal for many industries, including aerospace, automotive, and medical manufacturing.

With its ability to accurately shape and cut materials, the vertical milling machine is a great addition to any workshop. With the right setup and operations, it can be used to create a variety of complex and detailed parts.

Main Parts of Vertical Milling Machine

Since vertical milling machines are designed to manipulate large pieces of metal, they use a variety of different parts. Some of the most common ones include:

- Base: The base of the machine is the bottom supporting part that contains coolant and lubricant systems. It also holds the motor and other vital components that allow it to operate correctly.

- Column: The column is affixed to the top of the base and provides support to the knee with guideways. The ram is located on top of the column.

- Saddle: The saddle is located at the front of the column and serves as a base for the table where the workpiece is mounted.

- Knee: The knee is located at the bottom of the saddle and can be adjusted to support the table during different operations.

- Table: The table is used to hold the workpiece in place while it moves along the surface for cutting and drilling operations.

- Ram: This is at the top of the column to make an angle when cutting or drilling.

- Tool Head: This tool holder will keep your chosen tools in place while you work.

- Spindle: The Spindle is the component of a machine that helps in its rotation, usually driven by an electric motor. It is located in the headstock at the top front end of the machine.

Essential Vertical Milling Machine Controls

Geared towards larger projects, a vertical milling machine is controlled by several different components. The most essential ones are:

- Start/Stop: Green Start/Stop buttons are used to power the machine on and off.

- Hand Brake: After you turn the power off, press or pull the spindle brake to stop the spindle rotation and help remove collets and chucks. To lock the spindle, press the brake and then push it up.

- Cross-Feed Handwheel: The Cross-Feed Handwheel is for moving the table closer or farther away from you.

- Spindle Speed: To change the speed of the spindle, use the Spindle Speed wheel. You can change the speed for both high range and low range. Remember to keep the milling machine running when changing speeds.

- Forward/Reverse: The Forward/Reverse switch controls the direction of the spindle's rotation. When cutting in a high range, the switch should be in a forward position, but when working in a low range, it needs to be reversed. To change the spindle's direction while remaining in the same range, simply flip the switch to its opposite position.

- Power Feed: The power feed feature is present on some milling machines in the shop and uses a motor to control the machine's longitudinal feeding direction and speed.

Advantages of Using a Vertical Milling Machine

- Complex Operations: Vertical milling machines are great for complex operations, as they can perform many different functions. This includes engraving and drilling processes that require a high degree of precision.

- Multiple Materials: The vertical milling machine can be used to work on a variety of different materials, including steel, aluminum, and even plastics & wood. This makes it ideal for working on multiple projects or in different industries.

- Improved Accuracy: The vertical design of the machine ensures accuracy when it comes to the finished product. The cutting speeds can also be adjusted depending on the material being worked on, resulting in greater precision.

- Cost Savings: Using a vertical milling machine may result in cost savings as well. Generally, these machines are more cost-effective than their horizontal counterparts, requiring fewer resources and less labor to operate.

- Cut the Work Piece in Any Direction: The vertical milling machine allows you to cut the workpiece in any direction, including up and down, left and right. This can be beneficial when working on complex pieces or in tight spaces.

- Best for Heavy Cutting Jobs: No matter what project you're working on, the vertical milling machine is best for heavy-cutting jobs. It's able to handle bulky and dense materials with ease, making it ideal for any heavy-duty work.

Things to Consider Before Purchasing a Vertical Milling Machine

1. New or Used?

When looking for a vertical milling machine, one of the first considerations is whether to purchase a new or used one. While used machines may be cheaper in the short term, they may have a shorter lifespan or be more prone to breakdowns. Therefore, it's important to weigh up the pros and cons of each before making a decision.

2. Brand

Since efficiency matters in a machining job, the brand of the vertical milling machine is important. Different brands offer different features and specifications, so it's worth looking to buy from a proven manufacturer.

3. Dro and Power Feed

The Dro (Digital Read Out) and power feed are two main components to consider. The Dro is used for precision measurements and can control the spindle motor's speed. The power feed can be used for automated cutting, which can save time and money in the long run.

4. Size Matters

It may be tempting to buy a small desktop milling machine but don't if you want to mill metal. Consider how challenging it is to drill holes in steel or cut off pieces with a hacksaw--it requires quite a bit of effort. As you can imagine, trying to do those same things with a tiny machine wouldn't work well. That's why size matters. Always buy the biggest machine you can fit in your budget and space, as it will be worth its weight in gold.

Conclusion

The vertical milling machine is an incredibly versatile tool that can be used for a variety of jobs. It's ideal for complex operations, working with multiple materials, improved accuracy, and cost savings. It's also best for heavy-cutting jobs, as it can cut the workpiece in any direction.

So, when purchasing a vertical milling machine, consider the things we mentioned, like buying new or used, the brand, Dro and power feed, and size. These will help to ensure you make the right decision.

Meta Description

A vertical milling machine is used in the manufacturing industry to make precision parts. Learn more about this and other industrial machines on this blog!