Blog

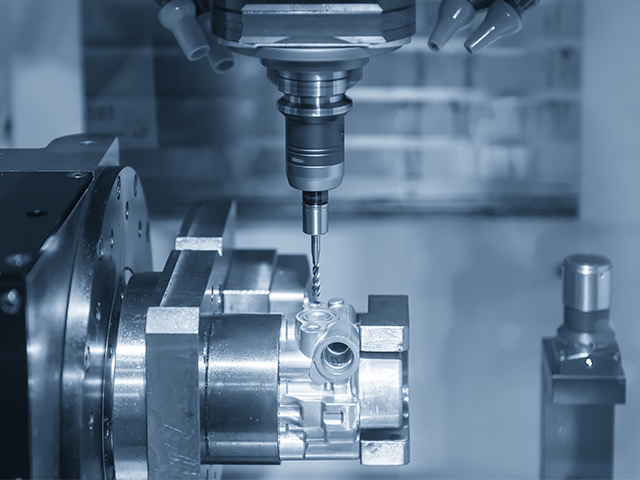

CNC Milling Head: Important Parts, Working and Perks of Using it!

2022.08.09

Main Parts of the CNC Milling Machine Head

Typically, a milling machine head can be separated into seven basic parts. These parts consist of:

- Knee: The knee can be adjusted but is fastened to the column. The worktable and saddle are supported by it. On the Z-axis, it can be lowered or lifted.

- Column: The machine's primary support structure is the column. It serves to strengthen the other machine parts.

- The Saddle: The saddle can be shifted parallel to the axis of the spindle and is positioned above the knee just below the worktable. If necessary, it shifts the workpiece horizontally.

- The Worktable: It is located on the point where the workpiece is connected, which is on top of the saddle. Depending on the model, the worktable of the milling machine can be moved vertically or horizontally.

- Spindle: This spinning part, which is propelled by an electric motor, holds either the machine tool or the arbour. One could say that the "heart" of a CNC milling machine is its spindle. The typical design consists of a rotating assembly and a tapered part where tool holders can be placed. Typically, the tool is linked to the spindle's shaft by a tool holder.

- Arbour: Machines that grind horizontally use arbour. It functions as a shaft that may be used to mount various machine tools when it is placed into the spindle.

- Ram: In vertical milling machines, the ram is typically found mounted to the top of the collum, which supports the spindle.

- Machine tool: The element that carries out the milling operation is the machine tool. It takes materials from the workpiece while being supported by the spindle. Machine tools come in a variety of types.

Working of a CNC Milling Machine Head

The object to be processed is mounted on top of the machine table according to the general operating concept for a CNC milling machine. It might be secured by vice or fixture, or it might be fastened to the table itself.

The machine reads coded instructions, executes them, and then begins the CNC milling process. The creation of a 3D CAD file illustrating the finished part is the first step. The design is then transformed into a machine-readable format after completion.

Following export to a CNC machine program, often in G-code format, CAM (Computer-Aided Manufacturing) software works on the instructions, guiding each movement the machine makes. This accurately and effectively reproduces the CAD design in the material of choice.

CNC milling head, which uses layering machining, can create both high and low volumes of extremely intricate and complex items. A revolving cylindrical tool called a milling cutter is used by the milling machine to remove material from a blank workpiece. The milling machine can operate along various axes and cut at various angles depending on the model being utilized.

Before getting into the milling machine for final manufacture, the finished part will have first been developed using CAD, or computer-aided design.

Advantages of Using a CNC Milling Head

Following are a few of the advantages of using a CNC milling head:

- Accuracy and Good Value are Guaranteed

High levels of accuracy and precision are inherent to the process of CNC machining, which leaves very little margin for error. This is because it uses a computer-driven program and inputs 3D designs created using CAD (Computer-Aided Design). An interface for the machine is used to start all operations.

Without requiring any input from the user, the machine follows these instructions. The highest level of precision is made possible by these automated procedures, ensuring that even the most complicated and finite geometry can be technically handled.

- CNC Milling Enables High Output Productions

Due to the automated methods used, CNC machines can function at a level that allows for large levels of production. If a product needs to be manufactured in large quantities while maintaining a high degree of commitment in terms of quality and finish, CNC milling is a reliable and well-liked alternative. A 3-axis machine may be operated and programmed with remarkable ease, providing excellent accuracy at a reasonable price.

- CNC Milling Requires Less Manual Work

Labor requirements for production are greatly reduced when a CNC milling machine is used. A CNC milling machine's tools can rotate at a maximum RPM (revolutions per minute) of thousands, producing a high production output while also helping to save time. No manual method could provide a result like that.

It's important to note that where less human involvement is required, the simpler the design becomes. For instance, if you had to manually work on a complex design, then machinists would be needed for moving the blank during the operation to verify that it was done securely and safely.

- Uniformity

The highest degrees of accuracy is needed when cutting away at the workpiece with CNC machining tools. Since the computer program controls the movement, every component is manufactured with the same level of accuracy. On a larger scale, components can be produced in large quantities with the assurance that every finished part will be of the same quality and finish.

Conclusion

In the computerized form of milling known as CNC (computer numerical control), a CNC machine head is programmed to perform the milling processes automatically. Several industries use CNC milling to perform a wide range of activities.

If you are looking for a CNC milling head to automate your production procedure then look no further and contact YIH KUAN today.